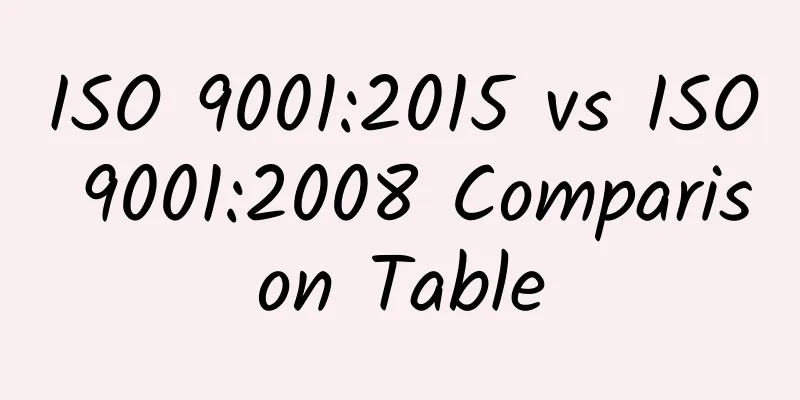

ISO 9001:2015 | ISO 9001:2008 |

1 Scope | 1 Scope 1.1 General |

4 Organizational environment | 4. Quality Management System |

4.1 Understanding the organization and its environment | 4. Quality Management System 5.6 Management Review |

4.2 Understanding the needs and expectations of stakeholders | 4. Quality Management System 5.6 Management Review |

4.3 Determine the scope of the quality management system | 1.2 Application 4.2.2 Quality Manual |

4.4 Quality management system and its processes | 4. Quality Management System 4.1 General requirements |

5 Leadership | 5 Management Responsibilities |

5.1 Leadership and commitment | 5.1 Management Commitment |

5.1.1 General | 5.1 Management Commitment |

5.1.2 Customer Focus | 5.2 Customer Focus |

5.2 Policy | 5.3 Quality Policy |

5.2.1 Establishing quality policy | 5.3 Quality Policy |

5.2.2 Communicate quality policy | 5.3 Quality Policy |

5.3 Roles, responsibilities and authorities within the organization | 5.5.1 Responsibilities and authorities 5.5.2 Management Representative 5.4.2 Quality management system planning |

6 Planning | 5.4.2 Quality management system planning |

6.1 Measures to address risks and opportunities | 5.4.2 Quality management system planning 8.5.3 Preventive measures |

6.2 Quality objectives and planning for their achievement | 5.4.1 Quality objectives |

6.3 Planning of Changes | 5.4.2 Quality management system planning |

7 Support | 6 Resource Management |

7.1 Resources | 6 Resource Management |

7.1.1 General | 6.1 Resource provision |

7.1.2 Personnel | 6.1 Resource provision |

7.1.3 Infrastructure | 6.3 Infrastructure |

7.1.4 Operational process environment | 6.4 Working Environment |

7.1.5 Monitoring and measuring resources | 7.6 Control of monitoring and measuring equipment |

7.1.5.1 General | 7.6 Control of monitoring and measuring equipment |

7.1.5.2 Measurement traceability | 7.6 Control of monitoring and measuring equipment |

7.1.6 Organizational Knowledge | No corresponding terms |

7.2 Capabilities | 6.2.1 General 6.2.2 Competence, training and awareness |

7.3 Awareness | 6.2.2 Competence, training and awareness |

7.4 Communication | 5.5.3 Internal Communication |

7.5 Documented information | 4.2 Documentation requirements |

7.5.1 General | 4.2.1 General |

7.5.2 Create and Update | 4.2.3 Document Control 4.2.4 Record Control |

7.5.3 Control of documented information | 4.2.3 Document Control 4.2.4 Record Control |

8 Operation | 7 Product Realization |

8.1 Operational Planning and Control | 7.1 Planning of Product Realization |

8.2 Product and Service Requirements | 7.2 Customer-related processes |

8.2.1 Customer Communication | 7.2.3 Customer Communication |

8.2.2 Determination of product and service requirements | 7.2.1 Determination of product-related requirements |

8.2.3 Review of product and service requirements | 7.2.2 Review of product-related requirements |

8.2.4 Changes in product and service requirements | 7.2.2 Review of product-related requirements |

8.3 Design and development of products and services | 7.3 Design and Development |

8.3.1 General | 7.3.1 Design and development planning |

8.3.2 Design and development planning | 7.3.1 Design and development planning |

8.3.3 Design and development input | 7.3.2 Design and development input |

8.3.4 Design and development controls | 7.3.4 Design and development review 7.3.5 Design and Development Verification 7.3.6 Design and development confirmation |

8.3.5 Design and development outputs | 7.3.3 Design and development outputs |

8.3.6 Design and Development Changes | 7.3.7 Control of design and development changes |

8.4 Control of externally provided processes, products and services | 7.4.1 Procurement process |

8.4.1 General | 4.1 General requirements 7.4.1 Procurement process |

8.4.2 Type and extent of control | 7.4.1 Procurement process 7.4.3 Verification of purchased products |

8.4.3 Information provided to external suppliers | 7.4.2 Procurement Information 7.4.3 Verification of purchased products |

8.5 Production and Service Provision | 7.5 Production and service provision |

8.5.1 Control of production and service provision | 7.5.1 Control of production and service provision 7.5.2 Confirmation of product and service provision processes |

8.5.2 Identification and traceability | 7.5.3 Identification and traceability |

8.5.3 Customer or external provider property | 7.5.4 Customer Property |

8.5.4 Protection | 7.5.5 Product protection |

8.5.5 Post-delivery activities | 7.5.1 Control of production and service provision |

8.5.6 Control of changes | 7.3.7 Control of design and development changes |

8.6 Release of Products and Services | 7.4.3 Verification of purchased products 8.2.4 Product monitoring and measurement |

8.7 Control of Non-Conforming Output | 8.3 Control of Defective Products |

9 Performance Evaluation | 8 Measurement, analysis and improvement |

9.1 Monitoring, measurement, analysis and evaluation | 8 Measurement, analysis and improvement |

9.1.1 General | 8.1 General 8.2.3 Process monitoring and measurement |

9.1.2 Customer Satisfaction | 8.2.1 Customer Satisfaction |

9.1.3 Analysis and evaluation | 8.4 Data Analysis |

9.2 Internal Audit | 8.2.2 Internal Audit |

9.3 Management Review | 5.6 Management Review |

9.3.1 General | 5.6.1 General |

9.3.2 Management review input | 5.6.2 Review Input |

9.3.3 Management review outputs | 5.6.3 Review Output |

10 Improvements | 8.5 Improvements |

10.1 General | 8.5.1 Continuous Improvement |

10.2 Nonconformities and Corrective Action | 8.3 Control of Defective Products 8.5.2 Corrective actions |

10.3 Continuous Improvement | 8.5.1 Continuous Improvement 8.5.3 Preventive measures |